My loving mother died 60 years ago when I was just 17. I remember well the day when she left us shattered and inconsolable. A mother like her is difficult to find anywhere in the world. Her wisdom, her goodness, her caring lives on to this day like a legacy of love that will always be with me. And that love surrounds me and brings me peace.

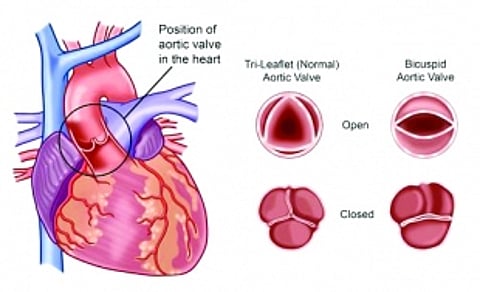

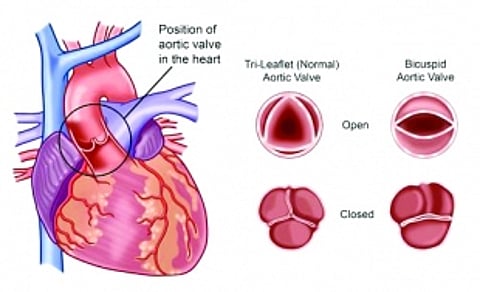

She was ailing from “Mitral Stenosis” (a choked mitral valve) due to rheumatic fever in childhood. There was then nothing else but medical treatment for this condition. Predictably, she went on deteriorating over the years and died in the end of acute pulmonary edema.

Sadly, valve surgeries were not being performed then. Today with the advancements the burden of valvular heart disease leads to over 300,000 heart valve replacements each year worldwide. The number will probably triple in 2050 and valvular heart disease is likely to be considered as the next cardiac epidemic.

There were two categories of “prosthetic” valves until now: mechanical and biological. The profusion of models in contemporary use is largely the result of failure to produce a single prosthesis with an optimal risk profile.

But now there’s good news: Dr K M Cherian, Chennai-based heart surgeon and the Vellore Institute of Technology, Chennai, have collaborated to develop a heart valve using 3D printing technology. Specialised biopolymers are used to manufacture it.

The project was undertaken in collaboration with the Centre for Automation and School of Mechanical Engineering at the Institute. Recently Cherian displayed a working prototype of the valve. Such valves are being developed using specialised computer-aided design software and modeling technique, based on MRI scan images of a human heart. The benefit is that it will exactly fit the dimensions of a patient’s heart. The process of patenting this 3D printed heart valve and testing it has been a stunning success.

The 3D printed heart valves, made with specialised biopolymers that are very similar to human tissue, can be directly implanted in heart patients requiring valve replacement. Cherian is the Indian heart surgeon who earlier performed India's first coronary artery bypass surgery and is considered a pioneer of pediatric cardiac surgery in the country.

"We are happy to announce we have designed and developed India's first 3D printed heart valve. We came up with four different prototypes and this is the fourth generation. It seems to be working well," said Dr Cherian, who has been researching on this project for about a year.

Dr Cherian claimed the 3D printed heart valve will revolutionise valve replacement surgeries and will considerably improve the chances of the body accepting the implant.

"Valve surgeries thus far being performed have drawbacks. After 5 or 10 years the “prosthesis” may get “infected” or “torn off”.

As to his inspiration, he said "we have been doing extensive research on the concept of 3D printing in the field of medicine." Earlier, 3D printing was used to plan the surgical approach, especially for complex procedures, in order to help cardiac surgeons and cardiologists to navigate and choose the best approach to treat heart diseases.

"This time, we focused our efforts on using 3D printers to manufacture heart valves using specialised biopolymers that are very similar to human tissue, which can be directly implanted in heart patients," he explained.

As this innovative procedure is being made under the "Made in India" programme, the cost of implant would be much lower than the imported heart valves currently used in India, he claimed.

The cost of imported surgically implantable heart valve ranges between Rs 45,000 (mechanical) and Rs 65,000-80,000 for animal tissue valve. Presently, they are imported mainly from the US.

Bioprinting is an emerging technology with various applications in making functional tissue constructs to replace injured or diseased tissues. It is a relatively new approach that provides high reproducibility and precise control over the fabricated constructs in an automated manner. During the bioprinting process, a solution of a biomaterial or a mixture of several biomaterials in the hydrogel form, usually encapsulating the desired cell types, termed the “bioink”, is used for creating tissue constructs. This “bioink” can be cross-linked or stabilised during or immediately after bioprinting to generate the final shape, structure, and architecture of the designed construct. “Bioinks” may be made from natural or synthetic biomaterials, or a combination of the two as hybrid materials. An ideal “bioink” should possess proper mechanical, rheological, and biological properties of the target tissues, which are essential to ensure correct functionality of the bioprinted tissues and organs.

Such advances in cardiology, even if they come at a cost are going to revolutionise the concept of valve implants to prolong lifespan and give a better quality of life to those who suffer from defective heart valves.

Like my beloved mother, so many with defective heart valves would have lived to this day. Yet, I must confess that love as powerful as that of a mother has left in me its own mark. To have been loved so deeply, even though the person who loved us is gone, gives me some protection forever. And this protection comes directly from Heaven above!

(Dr Francisco Colaço is a seniormost consulting physician, pioneer of Echocardiography in Goa)